Picking the Right Self-Adhesive Labels for Your Company and Personal Demands

Choosing the suitable self-adhesive labels for both organization and personal applications calls for a nuanced understanding of different variables that affect their efficiency. As we check out these important elements, it becomes clear that a tactical approach is necessary to ensure your tags not just satisfy expectations however also boost your overall branding and organization initiatives.

Recognizing Tag Products

When picking self-adhesive tags, comprehending the different label materials is vital to making sure optimal efficiency and sturdiness. The selection of material straight affects the label's look, functionality, and longevity. Usual label products include paper, polypropylene, polyester, and plastic, each offering distinctive advantages and downsides.

Polyester labels provide remarkable sturdiness, being resistant to tearing, dampness, and UV light. This makes them an outstanding selection for industrial applications or products that call for long-lasting labeling options (Self-Adhesive Labels). Polypropylene, while comparable to polyester, is usually less costly and offers an excellent equilibrium of resilience and print high quality

In addition, consider sticky kinds-- permanent, removable, or repositionable-- relying on your specific demands. Ultimately, selecting the appropriate label product is vital for attaining the wanted result, making sure that your tags do efficiently in their intended atmospheres.

Establishing the Right Size

Picking the ideal size for self-adhesive tags is a fundamental step that enhances the choice of tag materials. The size of a tag can considerably influence its functionality, exposure, and overall impact. It is vital to take into consideration the intended use of the tag when determining its dimensions.

To start with, examine the information that requires to be presented. Tags including even more text or graphics will need larger measurements to make certain readability and visual charm. Conversely, minimal layouts might profit from smaller labels that maintain a sleek aesthetic.

Furthermore, take into consideration the surface on which the label will be applied. Different surfaces, such as boxes, envelopes, or containers, might dictate specific dimension demands to make the most of attachment and exposure.

Furthermore, consider the quantity of tags needed; bigger tags might be extra cost-efficient for bulk printing.

Assessing Adhesive Stamina

Exactly how can one ensure that self-adhesive tags remain safely affixed in different problems? Reviewing sticky stamina is essential for guaranteeing that tags do efficiently, whether in a controlled setting or subject to severe temperatures, moisture, or various other variables.

As an example, detachable adhesives are optimal for tags that might require to be rearranged or gotten rid of without deposit, making them ideal for momentary applications. Alternatively, irreversible adhesives are designed to withstand different conditions and offer a strong bond, making them appropriate for long-lasting labeling requirements.

Testing the adhesive toughness can include peel adhesion tests, which determine the force called for to eliminate the label from a surface area. Eventually, selecting the appropriate sticky toughness makes sure that self-adhesive labels accomplish their function, keeping stability and presence these details throughout their designated lifespan.

Picking the Right Finish

The surface of self-adhesive labels plays a significant function in their overall efficiency and appearance, enhancing the sticky toughness formerly gone over (Self-Adhesive Labels). The choice of coating can influence not only the aesthetic impact of the tag however also its toughness and capability. Common coatings consist of matte, gloss, and semi-gloss, each serving different objectives

A matte coating supplies a non-reflective surface that is suitable for writing, making it appropriate for tags that require hand-written details. This surface likewise often tends to conceal fingerprints and spots, enhancing the label's appearance over time.

Alternatively, a gloss coating uses a shiny, vivid look that boosts color saturation, making it best for marketing labels that need to stand out. Nonetheless, this finish may be much less ideal for writing, as it can smear easily.

Semi-gloss surfaces strike a balance between both, providing a small sheen while maintaining excellent writeability. In addition, take into consideration variables such as dampness resistance and UV defense, particularly for tags subjected to severe atmospheres. By thoroughly selecting the right coating, people and companies can ensure their tags successfully share their designated message while maintaining longevity.

Considering Printing Options

Reviewing printing options is critical for optimizing the effectiveness of self-adhesive labels. The method you pick will substantially impact the top quality and sturdiness of the last product. Self-Adhesive Labels. Typical printing strategies include digital, flexographic, and thermal transfer printing, each offering distinctive advantages and factors to consider

Digital printing is ideal for variable information and brief runs, permitting for quick turnaround times and modification. This method makes it possible informative post for businesses to produce labels with high-resolution graphics and detailed layouts without incurring significant setup costs. Nevertheless, it might not be the most affordable alternative for bigger amounts.

Flexographic printing, on the various other hand, is well-suited for high-volume production. It uses adaptable alleviation plates to transfer ink onto numerous products, ensuring consistent top quality across huge sets. This technique is commonly favored for its efficiency and ability to publish on a variety of substrates, consisting of those with unique surfaces.

Thermal transfer printing is one more feasible choice, especially for labels that require toughness against severe conditions. This approach supplies exceptional print top quality and is frequently utilized for barcode and stock labels.

Eventually, choosing the best printing option hinges on your specific labeling demands, budget plan, and manufacturing quantity.

Final Thought

To conclude, picking the ideal self-adhesive tags demands mindful factor to consider of different aspects, consisting of tag materials, size, glue toughness, finish, and printing options. Each element plays an important duty in ensuring that the tags fulfill details business or personal demands effectively. By extensively examining these individuals, components and organizations can attain optimal outcomes, enhancing both capability and visual charm in labeling applications. Inevitably, educated selections cause greater satisfaction and success in tag application.

When selecting self-adhesive labels, understanding the various tag products is critical find out this here to making certain optimum efficiency and toughness.Picking the proper size for self-adhesive labels is a fundamental step that complements the selection of tag products. Inevitably, picking the ideal sticky stamina guarantees that self-adhesive labels satisfy their function, preserving stability and exposure throughout their designated lifespan.

The finish of self-adhesive labels plays a considerable duty in their overall performance and appearance, matching the sticky stamina formerly reviewed.In conclusion, choosing the proper self-adhesive tags requires mindful factor to consider of numerous variables, including tag products, dimension, glue toughness, coating, and printing choices.

Haley Joel Osment Then & Now!

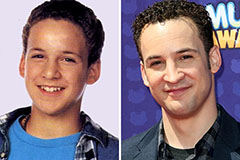

Haley Joel Osment Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Alexa Vega Then & Now!

Alexa Vega Then & Now! Kane Then & Now!

Kane Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!